MW Components - Greer: Springs

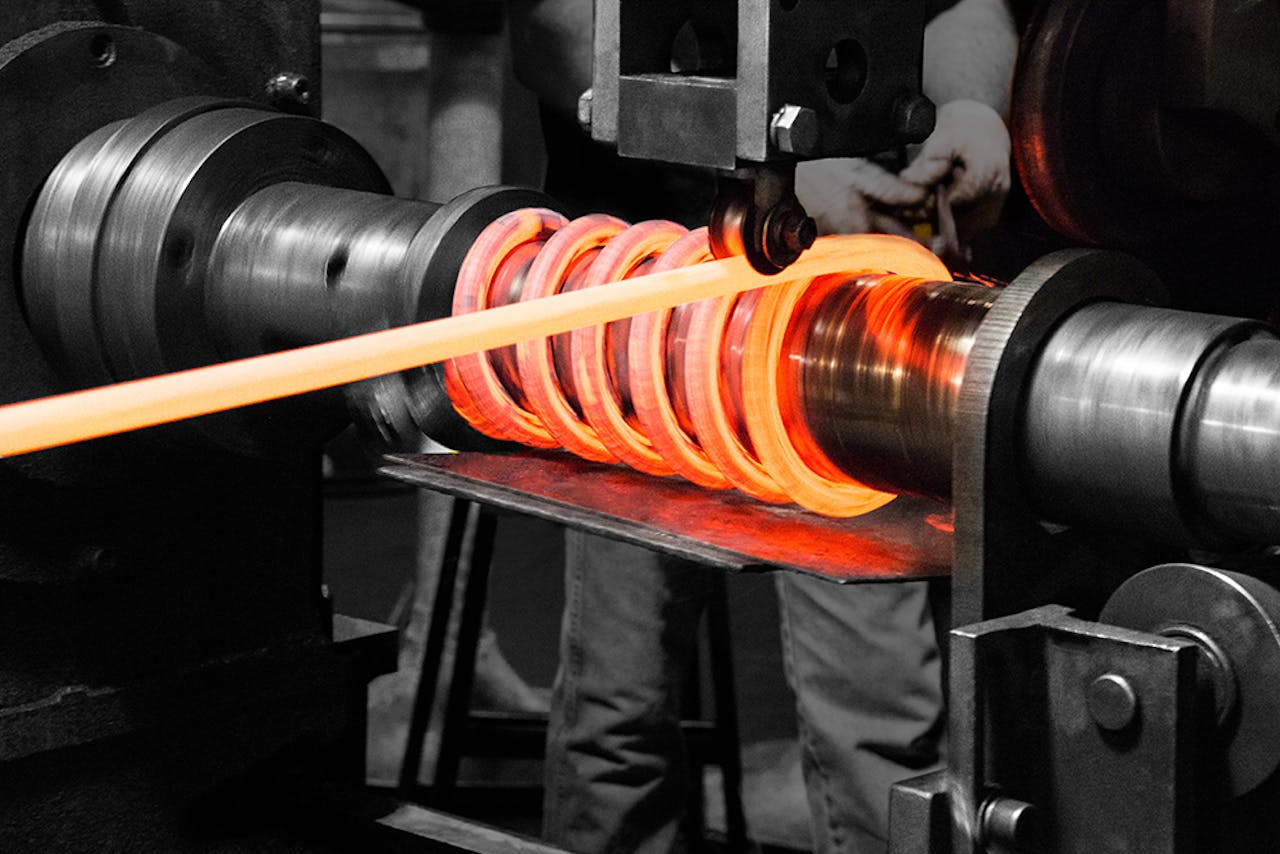

Hot Wound Spring Manufacturers, Formerly Duer Carolina Coil

With over 120 years of experience manufacturing cold and hot wound springs, MW Components - Greer: Springs, offers the highest quality custom springs made on the latest machinery. Greer: Springs, support quick turn prototypes and scalable production needs. Current lead times are just 2-6 weeks for many products.

Contact us to request a quote and start your project.

Our Products

-

We offer hot wound springs from 0.50” (12.7mm) to 3.125” (80.00mm) bar.

-

We manufacture variable pitch springs with spacing to your specs.

-

Our custom compression springs are available as hot or cold wound springs.

-

Our cold wound springs are manufactured in sizes from .250’’ (7mm) to .750 (18.75mm).

-

We produce pigtail springs with high tensile strengths, built to your specs.

-

As an expert custom spring manufacturer, we can produce specialty parts for your needs.

Superior Products & Support

ISO 9001

Certified Quality Processes

120

Years of Experience

20+

Countries Served

Made in the USA

Local Products, Local Experts

Dedicated to Excellent Service

At Greer: Springs, we pride ourselves on our ability to provide some of the best service in the industry. We provide high-quality products at a great value and our team is here to respond to any questions or concerns you have. Our commitment to excellence means we invest continuously in our people, processes, and machinery to be more efficient so we can deliver top quality products when you need them.

98% of clients surveyed said:

- We provide a high-quality product

- We provide a great value

- Our team is very responsive to customer questions and concerns

Get in touch with us for more information about how we can help you get the components you need, with the best possible experience.

Comprehensive Capabilities from Engineering Support to Fabrication

From engineering support to full-scale production, we can fulfill even the most specific requirements for coil spring manufacturing in industrial applications. With an array of hot and cold wound springs made on the latest machinery, our Greer: Springs location can support quick turn prototypes and scalable production needs.

In addition to manufacturing springs, MW Components - Greer: Springs serves as a partner for our clients during every step of their production processes. With some of the brightest engineering minds in the industry on our staff, we blend old-world craftsmanship and new-age innovation into every product we help produce. Our team’s engineers work with our clients’ engineers to optimize function, value and style. We can assist with concept development, design specification, and prototypes.

Our unmatched focus on client satisfaction and quick turnaround times make us the obvious choice for any of your engineered spring needs.

Custom Springs

Contact Us to Start Your Project

As engineering and manufacturing experts specializing in hot and cold wound springs, we offer high-quality, custom spring manufacturing to your specs. Our custom hot wound springs are available to be manufactured from 0.50” to 3.125” diameter bar, while our cold wound springs are available from 0.250” to 0.750”. Get in touch with us to discuss your application and specs.